The rise of electric trucks is transforming the transportation industry, heralding a new era of sustainability and efficiency. However, as electric trucks gain popularity, the effectiveness of their thermal management systems has come under scrutiny. This article explores how innovative technologies, particularly

high voltage electric compressors, can enhance battery performance and overall energy efficiency in electric trucks.

Understanding Thermal Management Systems

Electric trucks operate with a thermal management system that integrates three key components: the air conditioning system, the battery thermal management system, and the electronic control cooling system. These systems are essential for maintaining optimal operating conditions for the battery packs, which serve as the primary energy source. However, many technologies in the electric truck sector are still developing. The reliance on battery packs alone often leads to inefficiencies, as these three thermal management systems typically operate independently. This independence not only demands high space layouts but also results in low component commonality, leading to significant energy waste.

Challenges of Extreme Temperatures

One of the major challenges electric trucks face is their ability to withstand extreme temperatures. Battery packs, especially lithium batteries, are particularly sensitive to temperature fluctuations. Research shows that high temperatures can accelerate the aging of battery materials, causing a rapid decline in cycle life. Conversely, low temperatures can diminish the charging and discharging capacity of the batteries. When frequently operating in cold environments, the batteries may suffer irreversible capacity loss, severely impacting their lifespan. Therefore, maintaining optimal temperature ranges is crucial for ensuring battery performance and longevity.

The Role of Air Conditioning: The air conditioning system significantly impacts passenger comfort but also consumes a substantial amount of energy. In electric trucks, air conditioning can account for about 10% of the total energy consumption during the summer months. This energy demand can detract from the truck's overall range, making it essential to optimize energy consumption across all systems.

The Need for System Integration: Given the increasing demand for lightweight electric trucks and the stagnation of battery pack energy density, enhancing system integration becomes critical. Here, electric compressors present a promising solution. Unlike traditional compressors, electric compressors provide a more efficient means of temperature regulation, using less energy while delivering effective cooling and heating.

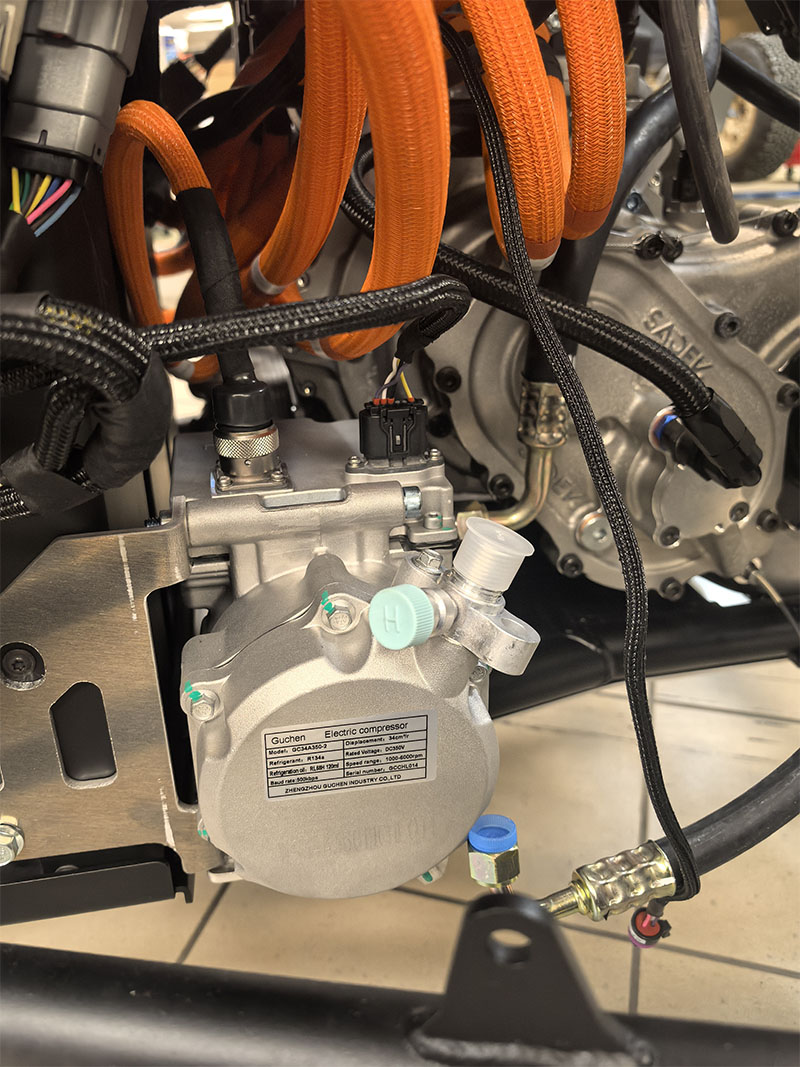

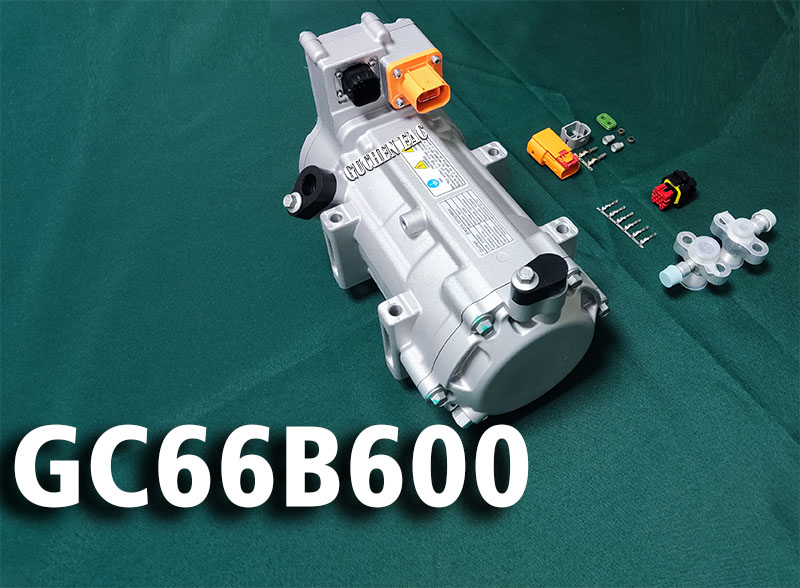

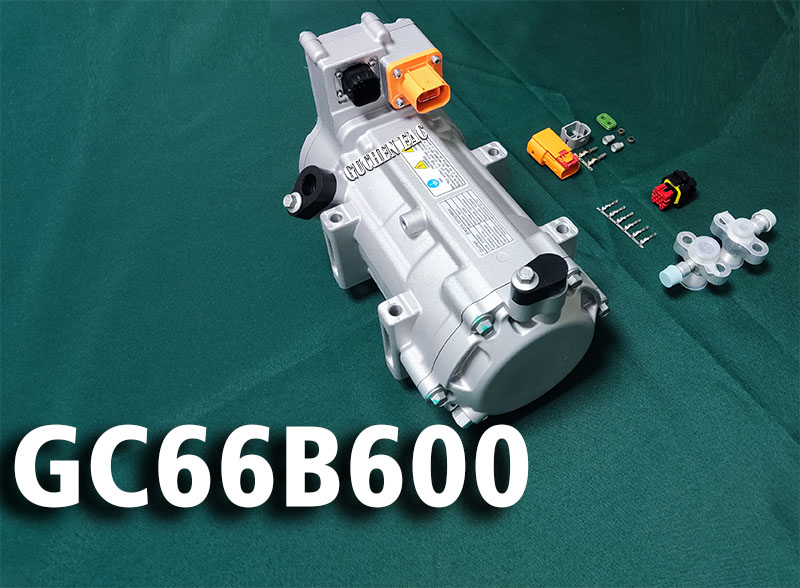

Among the innovative solutions available, the GC66B600 electric compressor stands out as a top choice for electric truck applications. With a displacement of 66CC, it is specifically designed for heavy-duty vehicles, ensuring robust performance in demanding conditions. The GC66B600 operates at a rated voltage of 600VDC, with a range from DC450V to 950V, enabling high-performance thermal management of air conditioning and high-voltage systems in battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs). Its advanced design allows for effective temperature regulation, enhancing overall energy efficiency while supporting the longevity of battery packs.

Electric compressors like the GC66B600 can optimize thermal management systems by improving overall energy efficiency in electric trucks. When integrated with the battery thermal management system, electric compressors can regulate temperatures more effectively. This capability reduces the strain on battery packs, helping them maintain optimal operating temperatures and extending their lifespan while minimizing energy waste.

Additionally, electric compressors can operate independently of the truck's engine, allowing for more flexible cooling and heating operations. This independence is particularly advantageous for electric trucks, where energy efficiency is paramount. By cooling or heating the cabin without significantly draining the battery, electric compressors enhance the truck's range and performance, making them more viable for long-haul operations.

Streamlining Design and Functionality

The integration of electric compressors also contributes to the overall design and functionality of electric trucks. By reducing the space required for traditional thermal management components, electric compressors facilitate a more compact and lightweight design. This shift not only improves energy efficiency but also aligns with the industry’s push toward sustainability and reduced carbon footprints.

In summary, the integration of electric compressors, such as the GC66B600, into the thermal management systems of electric trucks represents a significant advancement in optimizing electric vehicles. As electric trucks continue to evolve, focusing on system integration and energy optimization will be essential. By leveraging innovative technologies like electric compressors, the electric truck industry can enhance battery performance, improve passenger comfort, and contribute to a more sustainable future. Embracing these advancements is crucial for paving the way toward cleaner, greener transportation solutions, ultimately reshaping the electric truck landscape for the better.